Solution:

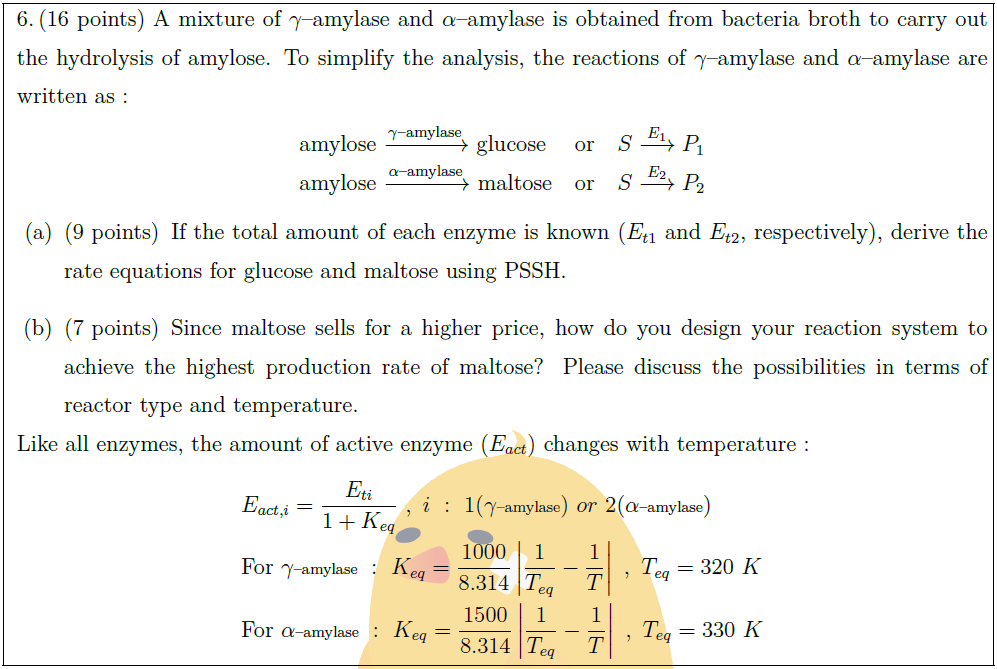

A mixture of $\gamma$–amylase and $\alpha$–amylase is obtained from bacteria broth to carry out the hydrolysis of amylose. To simplify the analysis, the reactions of $\gamma$–amylase and $\alpha$–amylase are written as :

\begin{center}

\begin{tabular}{@{}lll@{}}

amylose $\xrightarrow{\gamma \mbox{\scriptsize –amylase}}$ glucose & or & $S \overset{E_1}{\longrightarrow} P_1$\\

amylose $\xrightarrow{\alpha \mbox{\scriptsize –amylase}}$ maltose & or & $S \overset{E_2}{\longrightarrow} P_2$

\end{tabular}

\end{center}

\begin{parts}

\part [9] If the total amount of each enzyme is known ($E_{t1}$ and $E_{t2}$, respectively), derive the rate equations for glucose and maltose using PSSH.

\part [7] Since maltose sells for a higher price, how do you design your reaction system to achieve the highest production rate of maltose? Please discuss the possibilities in terms of reactor type and temperature.

\end{parts}

Like all enzymes, the amount of active enzyme ($E_{act}$) changes with temperature :

\begin{align*}

& E_{act, i} = \frac{E_{ti}}{1 + K_{eq}}\ ,\ i\ :\ 1(\gamma \mbox{\scriptsize –amylase})\ or\ 2(\alpha \mbox{\scriptsize –amylase})\\

& \mbox{For }\gamma \mbox{\scriptsize –amylase}\ :\ K_{eq} = \frac{1000}{8.314} \left| \frac{1}{T_{eq}} – \frac{1}{T} \right|\ ,\ T_{eq} = 320\ K\\

& \mbox{For }\alpha \mbox{\scriptsize –amylase}\ :\ K_{eq} = \frac{1500}{8.314} \left| \frac{1}{T_{eq}} – \frac{1}{T} \right|\ ,\ T_{eq} = 330\ K

\end{align*}